Top international trading and shipping organizations use drones in their warehouses to lower expenses, improve worker safety, and manage warehouses efficiently. To achieve these benefits, they apply drone management systems.

However, creating software systems for drone management is challenging. You need a team with relevant expertise in building embedded software, drivers, and cloud infrastructure. You might also decide to enhance your solution with data processing, AI, and blockchain, which requires a separate set of development skills.

In this article, we examine the key use cases of drone management systems, elements of drone management system architecture, and technologies to implement when building such a system.

This article will be useful for software development teams and organizations looking into the possibility of custom drone app development.

The role of drones in warehouse automation

The continuous growth of e-commerce is driving the rapid development of the logistics and warehousing industries. It’s no longer possible to manage deliveries using only human efforts.

That’s why modern warehousing heavily relies on information technologies like Internet of Things (IoT) systems to track, manage, and ship items as fast as possible. The warehouse automation and robotics market is rapidly growing: it is expected to cross $37.6 billion by 2030 according to a Businesswire report.

Drones are a large part of this market, as they help warehouse employees to:

- speed up their work

- improve warehouse efficiency

- reduce the risk of physical harm for humans

- reduce costs on warehouse management

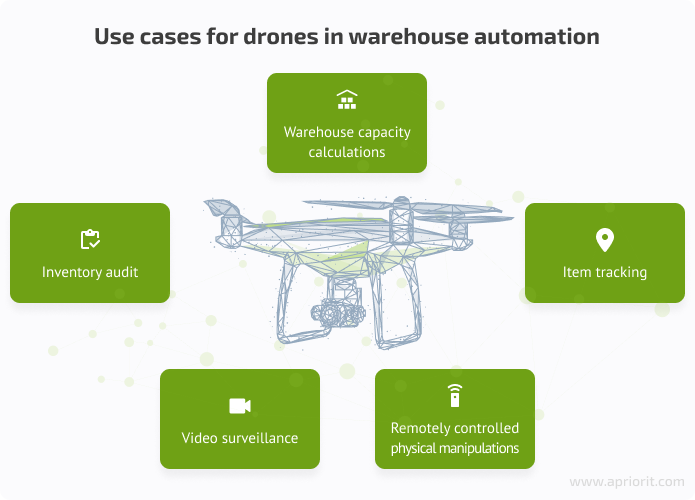

Using unmanned aerial vehicles (UAVs), or drones, allows warehouses to partially automate the following activities:

- Inventory audit. The primary use case for drones in a warehouse is scanning item barcodes and radio frequency identification (RFID) tags to calculate item quantities and record locations. Using drones instead of humans speeds up the process: a drone can move around the warehouse quickly and reach items stored in narrow corridors and on high shelves. It also reduces the risk of human error.

- Warehouse capacity calculations. Drones can distinguish between full and empty slots in a warehouse. Collecting data about the number and locations of empty slots in real time allows warehouse workers to efficiently store and ship items.

- Item tracking. Finding a particular box in a large warehouse is a time-consuming task even if an employee knows in what area it should be stored. A drone adds the exact location of each item to the warehouse database so it can find any box fast.

- Video surveillance. Every warehouse has a traditional surveillance system that relies on stationary cameras, which have their blind spots. Using drones makes warehouse surveillance more flexible and comprehensive, improving warehouse security.

- Remotely controlled physical manipulations. Warehouse workers can perform potentially dangerous tasks remotely using drones. UAVs built specifically for working in warehouses can lift and shift lightweight objects. They can also work in dangerous environments like dimly lit places, narrow passages, and high shelves.

To be able to perform each of these tasks, drones need complex management software that coordinates the hardware activities, collects data in real time, and constantly communicates with a warehouse management system (WMS). Let’s examine how these capabilities can be implemented within the architecture of a drone management system.

3 core elements of drone management system architecture

The architecture of any drone management software depends on its goals, use cases, and hardware capabilities. However, such systems have something in common. For instance, in terms of programming languages, developers prefer writing low-level code in C/C++. These languages are quite flexible and provide fine control over low-level processes.

Python is a popular choise for programming high-level functions. It’s a universal language that can help developers accomplish common tasks. However, it may be more convenient to use other languages for some specific development activities.

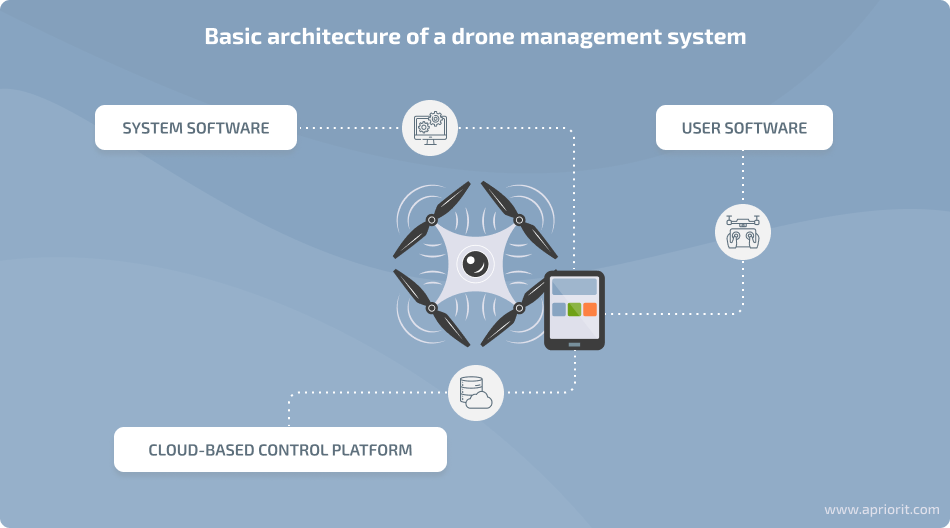

And when it comes to the system architecture, any drone management system consists of:

- System software

- User software

- Сontrol platform

System software

This is the foundation of a drone management system architecture that controls UAV hardware. It includes embedded software, drivers, an operating system, and APIs for communicating with the rest of the system.

This level of software manages basic drone operations:

-

- Flying

- Charging

- Navigating and calculating the drone’s location

- Scanning barcodes and taking pictures

- Collecting and transmitting data

- And more

Another goal of this type of software is to ensure secure collection of information. Embedded systems can be extremely vulnerable to hacking, as they have limited computing resources. Usually, they are equipped only with a small CPU and a small amount of memory. Overloading them with too many tasks creates delays in the real-time work of the system and may cause incorrect task execution.

Some developers neglect data protection features to use more resources for core system functionality, which leads to data leaks and breaches. But there are ways to secure collected information at the software level. You can learn more about embedded system security from our previous article:

User software

Software for users of drone management systems is designed to help warehouse employees remotely control drones. User software is usually delivered in the form of web and mobile applications. Developing these apps is similar to developing regular mobile apps.

To ensure precise control over UAVs, user applications need to communicate with drones in real time, support a stable internet connection, and have an easy-to-use and intuitive user interface.

Control platform

The control platform is the brain of the drone management system: it collects, processes, and stores data gathered by drones. It also helps users manage those drones. The platform can be hosted both locally and in the cloud.

The software elements of the control platform highly depend on the goals and target functionality of the drone management system. Such platforms usually include:

-

- Enterprise data management technologies and processing systems

- Artificial intelligence (AI) algorithms for data processing

- Navigation management

- Cloud infrastructure

- Communication protocols for exchanging data between drones, user apps, and the control platform

- APIs for integration with warehouse management systems

These three elements represent only the core of a drone management system. Within these elements, vendors implement various features and technologies to make their software more technologically advanced and competitive on the market. In the next section, we’ll take a look at the key drone management system features and technologies.

Key features and technologies to implement in a drone management system

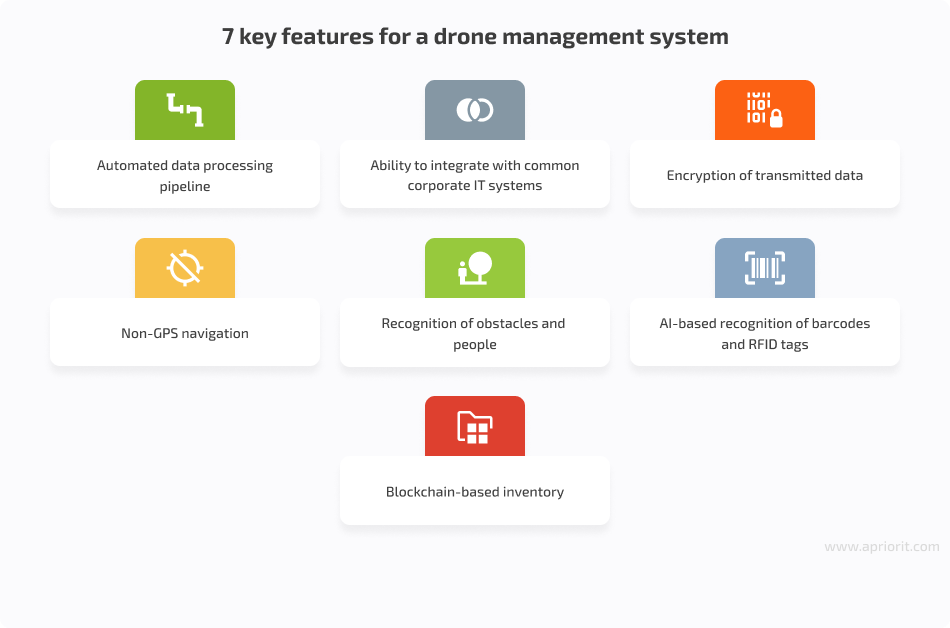

Modern drone management systems are technologically advanced solutions that operate using various drivers, AI algorithms, and even blockchain-based storage. Some technologies and features are a must for any drone management system. Others are optional, as they are needed only to perform a particular task.

Let’s take a look at the key features to keep in mind when creating a software system for drone management.

1. Automated data processing pipeline. A drone has to collect data about items in the warehouse and synchronize it with the warehouse management system and user application as fast as possible. When you create a drone data management software with an automated pipeline, data moves around the warehouse IT environment without any involvement from employees. In this way, the drone management system helps to keep the warehouse database up to date and eliminates the risk of human errors when manually inputting data.

2. Ability to integrate with common corporate IT systems. Building an end-to-end data transmission pipeline is impossible without the automated uploading of collected data to various IT systems. Some drone management systems allow only for data collection and leave the task of uploading this data to a warehouse management system, customer management system, or another system to warehouse employees. If done manually, uploading data takes a lot of time from employees and increases the risk of human errors. Support for various APIs helps to integrate your software with popular corporate IT products and allows you to automate data flows for your end users.

3. Encryption of transmitted data. Hackers may attempt to steal data collected by drones. To protect sensitive information from falling into the wrong hands, make sure that all data transmitted between drones, user apps, the control platform, and your WMS is properly encrypted.

4. Non-GPS navigation. Usually, drones rely on stable GPS connections to navigate. But it can be challenging in the warehouse because GPS signals are usually weaker inside a building. That’s why warehouse drones have to be equipped with distance sensors and embedded drivers that help the hardware to calculate the drone’s precise position.

5. Recognition of obstacles and people. Using drones in a warehouse can both make it a safer place for employees and endanger them. A drone has to be able to recognize objects on its route — including employees — and avoid them. To do that, a drone’s sensors should be able to measure proximity to the nearest objects, and the drone must be able to change its route accordingly.

6. AI-based recognition of barcodes and RFID tags. There are many issues a drone can face when scanning a barcode. The barcode may be placed upside down or in an unusual place on the box, or it may be in a non-standard format. Because of these issues, a drone may scan barcodes incorrectly or skip them altogether. Implementing AI-based optical character recognition and image recognition helps the drone management system better adapt to new conditions and efficiently process scans of various types.

7. Blockchain-based inventory. Keeping warehouse inventory organized and protected is another important task for drone management systems. Some vendors use blockchain-based systems, as this technology helps to protect data from undesired changes, theft, and hacking. Blockchain-based inventory gets data on items in the warehouse from drones and converts it into blocks of data that cannot be edited and tampered with.

These are just a limited set of features and technologies that you can implement during your warehouse drone management system development to make it secure, efficient, and convenient. However, this is not an exhaustive list of features — you should consider the demands and needs of your end users when deciding on the final set of capabilities for your WMS.

If you’re also interested in improving your application’s cybersecurity, check out our article about heap spray techniques and how to fight them.

Conclusion

Drone management systems help warehouse employees perform their jobs faster, safer, and more efficiently. UAVs partially automate inventory audits, warehouse capacity calculations, video surveillance, and lots of other activities.

The architecture of any drone management system consists of three major elements: system software, user software, and a control platform. Inside these elements, vendors deploy all sorts of technologies and features to adapt their drone management systems to the demands of warehouse owners.

Developing such a technologically advanced product requires experts with relevant experience and diverse skill sets. At Apriorit, we have what it takes to develop a comprehensive drone management system, with expertise in everything from embedded and IoT solutions and cloud infrastructure management to artificial intelligence and blockchain. We also have real-life experience in the development of a drone battery charging system.

Reach out for a consultation and expert assistance with building your solution!