Key takeaways:

- Predictive maintenance uses real-time data and advanced analytics to anticipate possible vehicle issues before they can cause costly downtime or incidents.

- Automotive companies can leverage predictive maintenance to optimize production and operational processes.

- Core technologies enabling predictive maintenance include telematics, IoT, machine learning, and AI-powered analytics.

- Automotive companies may need expert assistance with implementing technology, processing data, and ensuring cybersecurity to address challenges that emerge when adopting predictive maintenance.

Keeping your vehicle fleets fully operational, safe, and efficient while not overspending on maintenance is a true challenge for automotive companies. Traditional reactive maintenance is inefficient and costly, as emerging issues are addressed only after they occur. As an alternative, more and more automakers and fleet managers are adopting predictive maintenance, aiming to anticipate and deal with potential problems before they manifest.

But how can you implement such a system? What should be your first steps? In this article, we answer these questions and discuss the real benefits of adopting predictive maintenance for automotive businesses (and what challenges to expect along the way).

This article will be helpful for automakers and fleet managers who want to evaluate the need for predictive maintenance in their operations and determine their first moves on this challenging journey.

Contents:

- What is predictive maintenance?

- Benefits of predictive maintenance for automotive companies

- How does predictive maintenance work in automotive systems?

- Steps to build an efficient predictive maintenance solution

- Challenges in adopting automotive predictive maintenance

- Get a reliable partner for your automotive projects

- Conclusion

What is predictive maintenance?

Predictive maintenance is a proactive approach to equipment maintenance. It’s a set of specific procedures that, in contrast to traditional reactive approaches, aim to anticipate possible equipment failures before they occur. To achieve this, predictive maintenance focuses on three things:

- Continually monitoring components and systems

- Gathering real-time data about their current state

- Forecasting the need for maintenance with the help of advanced data analytics

This approach has been widely adopted across various sectors where manufacturers and service providers leverage complex equipment and technical systems, specifically when elevating data analytics in the automotive industry. According to a report by Stellar Market Research, the market for predictive maintenance in the automotive industry will reach over $130 billion by 2030, showing an impressive 21% growth from 2024 to 2030.

OEMs, logistics operators, and other automotive businesses leverage advanced predictive maintenance systems to automate the collection and analysis of data from vehicle sensors, thus enabling proactive responses to possible anomalies and failures. The market already offers some ready solutions for automotive predictive maintenance, including from vendors like Samsara, Force Fleet Tracking, and Upstream. However, as most off-the-shelf products tend to focus on a limited number of features, manufacturers and fleet managers with robust needs often choose to invest in a custom solution.

Want to build custom automotive software?

Delegate this task to Apriorit’s cybersecurity and technology experts to get a high-quality, reliable, and secure automotive product that perfectly fits your business needs and allows you to rule the market.

Benefits of predictive maintenance for automotive companies

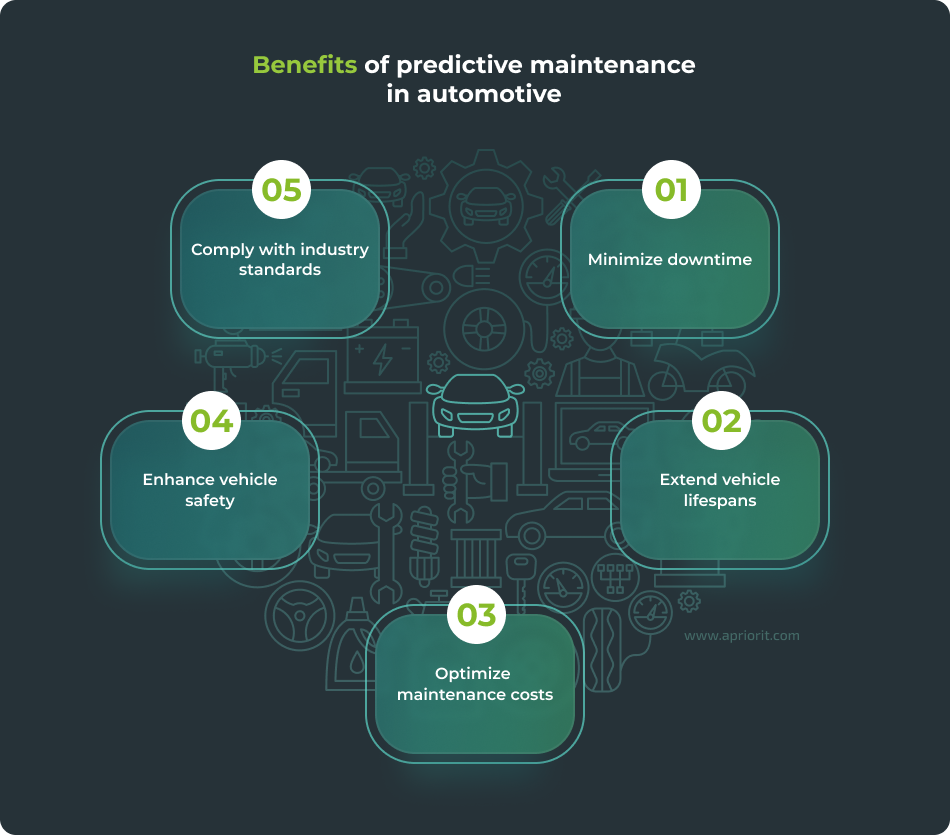

Adopting predictive maintenance for vehicles brings numerous benefits to OEMs and other automotive businesses:

1. Minimize downtime — Even when a component or system operates normally, an advanced data analytics system can detect early signs of potential malfunction, helping to prevent unexpected downtime or equipment breakdowns. This is especially crucial for commercial fleets, where any downtime results in significant revenue losses.

2. Extend vehicle lifespans — With ongoing monitoring and analysis, automotive companies can intervene in a timely manner to keep critical vehicle components and systems in optimal shape, prolonging their operational lifespan.

3. Optimize maintenance costs — By detecting and addressing component wear or breakage early on, automotive companies can avoid expensive emergency repairs, optimize their parts replacement cycles, and avoid costly over-maintenance.

4. Enhance vehicle safety — Early identification and fixing of potential malfunctions in critical systems also enhances vehicle safety, helping automotive companies prevent accidents. This way, businesses can secure not only their assets but also their drivers and passengers.

5. Comply with industry standards — The automotive industry is highly regulated; manufacturers and logistics companies must meet tough security and emissions standards. Predictive maintenance helps them continually monitor vehicle performance and stay in compliance with evolving regulations.

Before evaluating various implementation options, let’s first analyze the main aspects of predictive maintenance for automotive systems.

Read also

Automotive Software Development: Trends and Challenges

Get a sneak peek at the technology trends and challenges shaping the future of the automotive industry to make better-informed decisions for building your next automotive software solution.

How does predictive maintenance work in automotive systems?

Predictive maintenance systems analyze multiple factors, from historical data to a component’s current state and the specifics of its use, to forecast potential issues and optimize vehicle maintenance efforts.

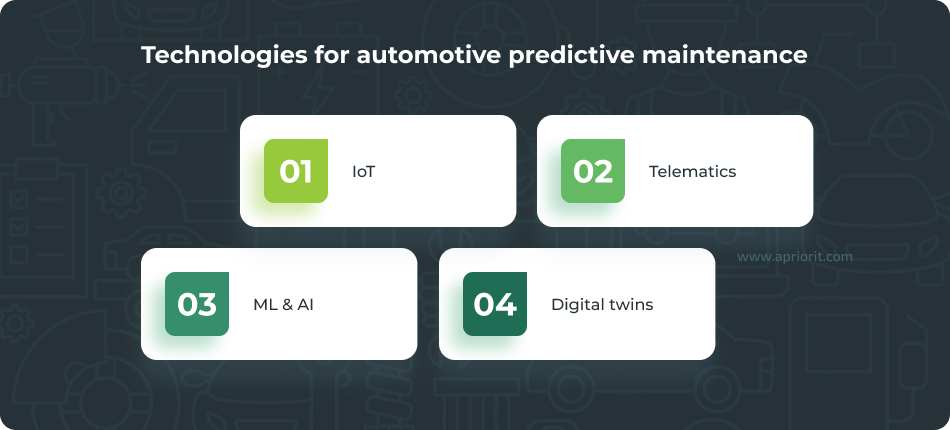

Core technologies a modern automotive predictive maintenance system can rely on include:

Internet of Things (IoT) — IoT sensors enable continuous monitoring of critical vehicle components, helping to assess the health of a particular system. They usually monitor specific metrics like temperature, pressure, wear rate, or vibration. In vehicles, IoT sensors are often embedded in engines, brakes, suspension systems, and electrical circuits.

Telematics — Telematics systems also gather and transmit real-time monitoring data from vehicles to central systems. Some telematics systems collect fuel consumption, routing, and GPS data from various system devices, while others leverage edge-enabled IoT. The use of telematics allows automakers and fleet managers to assess parameters like battery voltage, engine temperature, tire pressure, and brake performance and get alerts about detected anomalies.

Machine learning (ML) and artificial intelligence (AI) — Predictive maintenance systems leverage various machine learning models and artificial intelligence techniques to analyze extensive sensor data, look for patterns in it, and forecast potential failures. AI-driven analytics enhance this by continually learning from gathered data to discover new patterns and increase prediction accuracy.

Digital twins — A digital twin simulates specific scenarios or stress conditions, helping to evaluate a vehicle’s performance, detect possible anomalies, and optimize maintenance plans. While digital twins aren’t a mandatory part of a predictive maintenance system, they are often used to provide a holistic view of an asset’s health.

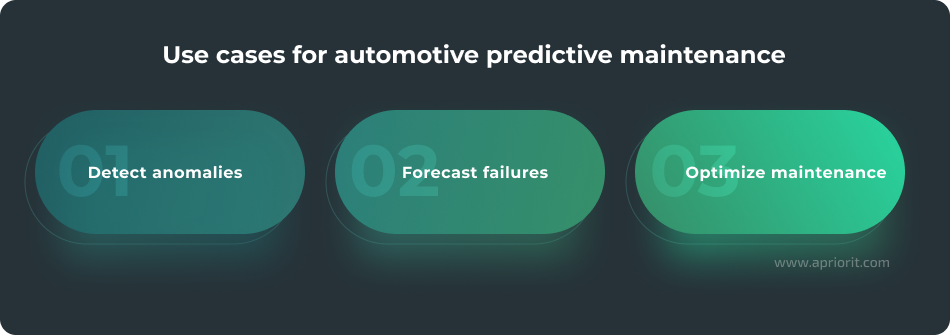

Also, predictive maintenance systems often deploy additional monitoring tools, such as infrared thermography to analyze temperature changes or acoustic monitoring to locate possible leaks or stresses. Leveraging these and other technologies, automotive systems can address three core use cases:

1. Detect anomalies — Detecting unusual patterns that may indicate potential failures or malfunctions is one of the main tasks for predictive maintenance in automotive. Dedicated solutions process data received from IoT sensors embedded in critical vehicle components, establish a baseline for normal vehicle performance, and then use that baseline to detect anomalies. When an anomaly is detected, fault diagnosis algorithms analyze the data to pinpoint the source, helping technicians understand which components require their attention.

2. Forecast failures — Predictive maintenance can also help with anticipating potential failures and estimating the remaining lifespan of particular components or vehicles. By leveraging machine learning models and AI-based analytics, a predictive maintenance system can forecast when components are likely to wear out. This allows businesses to schedule parts replacement before issues escalate and therefore prevent dangerous on-the-road breakdowns.

3. Optimize maintenance — Once a system detects potential failures and forecasts their timeline, automotive companies can efficiently optimize their existing maintenance schedules. As a result, they can minimize fleet downtime and align their maintenance efforts with operational demands, including better planning the restocking of parts.

Consider investing in a custom product to ensure your predictive maintenance solution covers all business and technical needs. The next section outlines the essential steps to build such a solution.

Read also

Generative AI vs Predictive AI: Which to Choose for Your Business

Discover the practical applications of generative and predictive AI and understand the unique advantages each brings to analytics, creative tasks, and predictive modeling.

Steps to build an efficient predictive maintenance solution

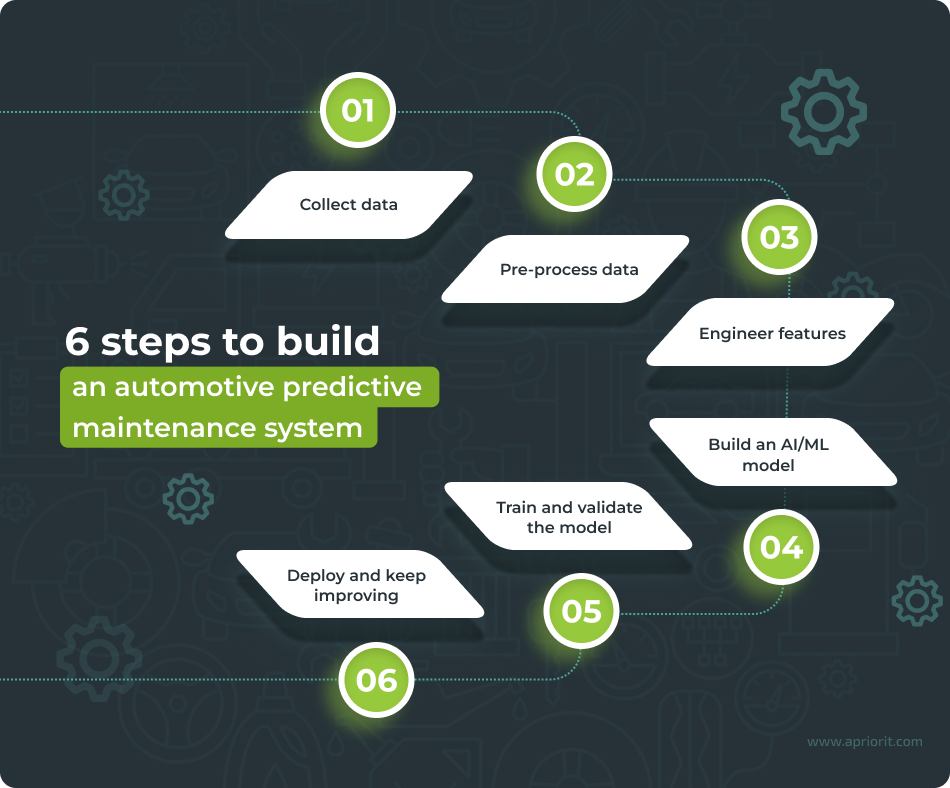

Features integrated into your predictive maintenance solution can vary depending on your business needs. Yet the general process of building a solution to anticipate possible vehicle breakdowns and optimize maintenance usually includes these steps:

1. Collect data — High-quality, relevant data is the foundation of any predictive maintenance solution. For the final system to accurately and timely predict possible issues, it’s crucial to continuously feed it with vast amounts of data from IoT sensors, telematics systems, and digital twins. Depending on what predictions you want your system to make, you’ll need to determine what data you need and which sensors and systems to get it from.

2. Pre-process data — The quality of data has an immense impact on the performance of machine learning models. Raw data usually requires additional cleaning and formatting before it can be used for further analysis. Common activities at this step include removing inaccuracies and inconsistencies, handling missing values, getting rid of irrelevant or redundant information, and standardizing data formats.

3. Engineer features — Features are specific variables in the pre-processed data that a model will learn during training. Effective feature engineering enables the model to accurately identify trends and detect potential issues. Using existing data, your team can find or create new features that may capture data patterns related to the health of specific components or the vehicle in general.

4. Build an AI/ML model — While it’s possible to use manual data analysis and complex statistical models to forecast vehicle issues, machine learning algorithms allow for increasing the speed and accuracy of such predictions. A predictive maintenance system can leverage different types of AI or ML models, from decision trees and regression models to neural networks. The choice will depend on the complexity and nature of the data you’re working with.

5. Train and validate the model — Training is an essential step in which a model learns to recognize factors that contribute to potential failures and component wear. During validation, the model is tested with new data to verify the accuracy of its predictions. To improve the accuracy and reliability of a model, your team may need to fine-tune it, adjusting different model parameters or even retraining the model with new, revised data.

6. Deploy and keep improving — Once you deploy your model, it’s important to keep fine-tuning and improving it so that it can better handle new real-world data, respond to evolving patterns, and stay reliable. The overall system will also need regular updates to enhance data security, improve performance, and introduce new features if needed.

These are just the basic steps necessary to deliver an efficient system that can make accurate and reliable predictions. However, integrating predictive maintenance capabilities into an automotive system is associated with a number of challenges. We discuss them in the next section.

Read also

How and Why Should You Build a Custom XDR Security Platform?

Take your cybersecurity to the next level with an in-depth look at XDR platforms. Explore how an XDR platform can transform your threat response capabilities, improving detection and response accuracy.

Challenges in adopting automotive predictive maintenance

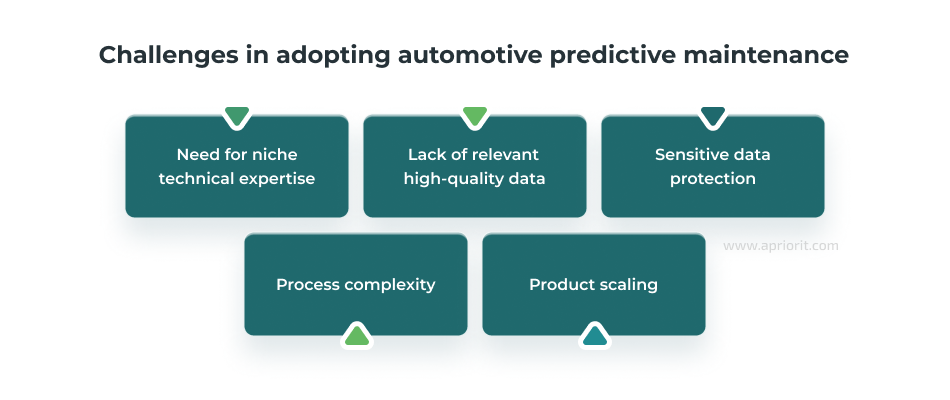

Depending on the complexity of the desired system and the competencies available within their in-house teams, automotive businesses may face various challenges when adopting predictive maintenance for their software systems.

1. Need for niche technical expertise — Delivering, deploying, and maintaining an efficient predictive maintenance system requires specialized skills and knowledge in several fields. In particular, to ensure safe integration and secure performance of your product, you may need to enhance your team with expertise in:

- Embedded systems and IoT for working with component sensors

- AI and machine learning for building and training your models

- Reverse engineering and cybersecurity for enhanced protection of critical data and systems

- And more

2. Lack of quality relevant data — Predictive maintenance systems rely heavily on the data received from vehicle components. Yet to ensure the system’s efficient performance and accurate predictions, that data must be reliable, relevant, and of high quality. Obtaining high-quality data in real time can be a true challenge, especially when you need to work with older vehicle models that use outdated sensors.

3. Sensitive data protection — Connected vehicles can be a tempting target for cybercriminals. With the continuous collection and processing of various types of vehicle data, from component performance to driving patterns, there are many security and data privacy concerns that need to be addressed at the development and testing stages. Implementing additional security measures at every stage of the software development lifecycle will help strengthen data protection and mitigate emerging threats in a timely manner.

4. Process complexity — Predictive maintenance systems involve different technologies and complex processes that must work seamlessly together. Integrating these systems with existing automotive operations adds another layer of difficulty, as it requires integrating new features with traditional workflows and your existing IT infrastructure. Optimizing these processes without compromising the system’s performance, safety, or prediction accuracy is challenging.

5. Product scaling — Last but not least, eventually any predictive maintenance system will need to scale, whether to support higher loads or expand the range of supported vehicles. If scaling opportunities weren’t properly planned at the design stage, maintaining high-level performance and security while scaling can put a heavy load on your development team and increase the project’s budget.

Related project

Custom Cybersecurity Solution Development: From MVP to Support and Maintenance

Explore our approach to building a comprehensive cybersecurity solution that strengthens data protection and enhances system integrity.

Get a reliable partner for your automotive projects

As you can see, designing, building, and integrating a reliable and secure solution for predictive maintenance is a complex and challenging task that requires high-grade experts from various fields. If you don’t have the necessary expertise in your in-house team, Apriorit is here to help.

As a software development company with TISAX certification, we are fully equipped to help automotive companies tackle their most challenging tasks. Apriorit experts will gladly assist you with:

- Custom development and prototyping — Our experts will help you design and prototype robust predictive maintenance systems. You can delegate any task to us, from IoT sensor integration to real-time data analytics, and be sure that the delivered solution will exceed your expectations.

- AI development and integration — Our AI engineers can help you build, train, and fine-tune a custom model from scratch or adjust an open-source solution to your needs. We will also assist with integrating the new system into your existing environment while ensuring great performance and strong cybersecurity.

- Security testing and quality assurance — Leveraging our extensive cybersecurity expertise, you can deliver high-quality custom solutions, audit and test the security and reliability of your existing products, and ensure that your software meets strict data security and privacy requirements of relevant standards and regulations, including ISO 26262, ISO/SAE 21434, and AUTOSAR.

With Apriorit, you can form a dedicated team with all necessary specialists on board, from business analysts and project managers to experts in architecture design, reverse engineering, embedded software development, and AI.

Conclusion

Predictive maintenance represents a transformative shift from the reactive measures historically taken by automotive companies to proactive vehicle management, where potential issues and breakdowns are addressed long before they would occur. This new approach offers automakers and fleet managers an efficient way to optimize their budgets while improving vehicle safety and performance.

Automotive predictive maintenance solutions are highly complex. They rely heavily on real-time data from IoT sensors and telematics systems and leverage advanced technologies like digital twins and AI-powered analytics to anticipate potential issues and improve maintenance planning. As a result, building such a solution requires extensive expertise in various fields, from embedded software and cybersecurity to AI and ML.

Working with Apriorit, you can form a dedicated team of experts with the skills and knowledge required to assist you with implementing any feature or software solution that your business needs. Let us help you transform your automotive data into actionable insights that will drive your vehicles’ efficiency, safety, and reliability.

Need a reliable tech partner for your next automotive project?

Apriorit provides advanced automotive software expertise to support safety, connectivity, and innovation in every aspect of vehicle technology.