The diversity of types of automotive businesses and their tasks often makes generic off-the-shelf enterprise resource planning (ERP) solutions insufficient. Custom ERP systems are better suited to address unique automotive workflows and challenges, offering tailored functionality for optimal performance. However, building one is no small task.

In this article, Apriorit experts discuss the role of ERP systems in the automotive industry, key use cases, must-have features, and development challenges. They also share general know-how as well as experience-based tips and insights.

This article will be useful for technical leaders of automotive manufacturers and suppliers who are looking for software that will make their businesses more organized and competitive.

Contents:

How do ERP systems benefit automotive companies?

Enterprise resource planning (ERP) systems are essential for modern automotive businesses aiming to streamline operations, improve efficiency, and reduce costs — crucial factors in an industry undergoing rapid changes. ERP solutions help businesses adapt to evolving demands for vehicle security, diversity, and new smart features.

Enterprise resource planning software is designed to manage various business processes in real time. Depending on its needs, an organization can integrate an ERP system into procurement, production, distribution, customer relationships, and other operations. An ERP solution continuously collects data on these operations, allowing users to review and adjust them in real time.

Automotive businesses increasingly adopt ERP solutions because they provide control over constantly changing workflows and processes. A 360 Market Updates survey estimates that the automotive ERP market was worth $3 billion in 2022 and will increase to $4.6 billion by 2031.

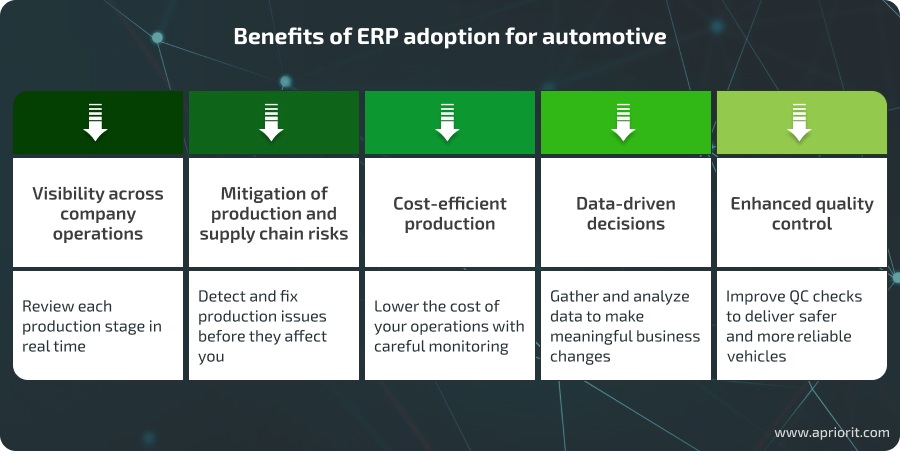

Here are the key benefits of using ERP systems in the automotive industry:

Looking for ways to streamline an automotive business?

Partner with Apriorit specialists to develop a custom ERP solution tailored to your business challenges, regulatory requirements, and needs.

Use cases for an automotive ERP solution

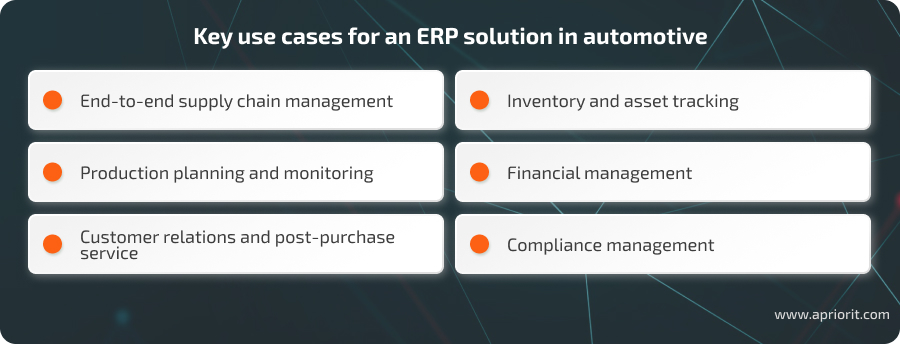

Automotive companies are diverse, with completely different production operations for OEMs and Tier 1 and Tier 2 suppliers. While companies can find unique use cases for an automotive ERP system, most automotive businesses can adopt such a system for the following purposes:

End-to-end supply chain management. An ERP system centralizes supply chain management across the whole organization, from procurement to distribution. It provides automotive companies with real-time data on parts procurement and use, detected issues, storage time, etc. This data helps companies track their purchases, detect and resolve supply chain bottlenecks, and optimize spending. When combined with predictive maintenance systems, an ERP also allows businesses to anticipate demands for certain parts and fine-tune their delivery for just-in-time repairs.

Inventory and asset tracking. Automotive companies use hundreds of thousands of parts across different warehouses and production sites. Confusion and chaos with asset tracking can cost a company lots of money and slow down production. An ERP system enables real-time tracking of all parts, tools, and materials produced or purchased by a business. For example, an ERP solution can ensure that high-value components like engines or electronics are accounted for at every stage.

Advanced tracking features, including radio frequency identification (RFID) and Internet of Things (IoT) integration, improve the accuracy of real-time visibility into stock levels and asset conditions, reduce waste, and optimize storage costs.

Production planning and monitoring. Errors and delays in automotive production can cost a company millions of dollars and undermine its reputation. ERP systems integrate data from design, procurement, and inventory processes to help users create accurate production schedules. Real-time monitoring ensures that potential issues, such as machine downtime or supply delays, are detected early and taken into account. This way, an ERP solution enables just-in-time manufacturing, reduces operational inefficiencies, and improves product quality by ensuring each stage of production adheres to precise specifications.

Financial management. ERP systems often come with integrated accounting, budgeting, and reporting features, helping automotive companies control and plan their spending. For example, an ERP system can track in real time how much a company spends on parts procurement, how much money is sitting in warehouses in the form of assets, and how much revenue can be expected during a certain period. Automated compliance tools ensure that financial records align with regional tax codes and industry standards, reducing the risk of audits or penalties.

Customer relations and post-purchase service. Building long-term customer relationships with fleet operators and automotive dealerships is key for any vehicle manufacturer. ERP systems can manage sales, service history, and customer feedback. Alternatively, they can integrate with a company’s customer relationship management (CRM) solution to provide information on shipments and services. These features help automotive companies streamline sales and post-purchase services such as warranty claims or maintenance scheduling, enhancing customer satisfaction.

Compliance management. Automotive manufacturing is a heavily regulated industry where most companies have to adhere to ISO 9001, ISO 26262, and AUTOSAR. These and other standards impose numerous requirements that are difficult to track manually. An ERP system allows manufacturers and suppliers to analyze their production flows, detect cases of non-compliance, and find ways to fix them. ERP solutions can also generate documents for auditing and reporting, helping companies to achieve and confirm compliance.

An ERP system needs a comprehensive and well-thought-out set of features to be useful for this variety of use cases. Though each solution on the market has its unique features, let’s take a look at the most common ones.

Read also

Automotive Software Development: Trends and Challenges

Apriorit experts explore how to develop a successful custom automotive solution for the modern market. Discover key trends and challenges as well as the benefits of committing to a custom solution.

Must-have ERP features for automotive

ERP solutions often have a modular architecture that allows users to pick which features their business requires. This modularity allows businesses to adjust an ERP system to their facilities and not overspend on unnecessary features. For example, if a business doesn’t want to add RFID tags to all of its parts and manufactured goods, it doesn’t need an RFID tracking system; if a business uses a CRM or accounting software, they need an ERP solution with corresponding integrations.

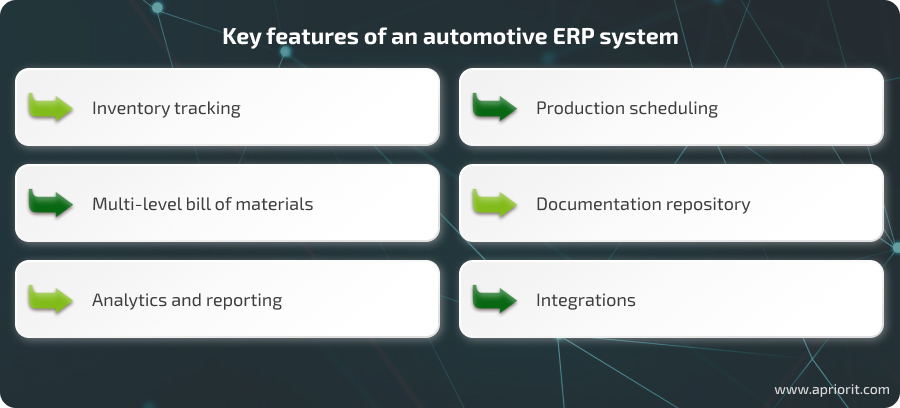

Automotive companies usually look for ERP systems with the following features:

Inventory tracking. This feature helps automotive specialists locate parts or tools in real time. It saves employees time searching for items, ensures that nothing is lost in a huge warehouse or production facility, and prevents overstocking and understocking.

Inventory tracking is usually based on data from IoT sensors, RFID tags, or GPS modules, which can provide information on an object’s location and condition. Some ERP systems go beyond simple tracking and counting and use machine learning algorithms to forecast wear and tear on tools and demand for parts, thus streamlining procurement.

Production scheduling. Automotive manufacturing requires precise coordination across assembly lines, supplier deliveries, and quality checks. ERP systems enable real-time scheduling based on resource availability, machine capacity, requirements of different manufacturing processes, etc.

Scheduling features rely on data from IoT sensors on production lines to control and visualize production processes. They can also use data analysis algorithms or AI to assess the efficiency of planned production scenarios and suggest improvements.

Multi-level bill of materials. A bill of materials (BOM) is a document that describes all components and subcomponents used in the production of a vehicle. Automotive companies have to maintain hardware BOMs, which detail everything used in the physical production of each unit, and software BOMs, which describe the frameworks, libraries, and tools used during automotive software development.

An ERP system can create a database that organizes components into multiple levels and allows for detailed tracking of each assembly stage. With indexing, it can also automatically update BOMs and synchronize them with production plans to reflect changes in real time.

Documentation repository. An automotive business has to document each step of its operations, from signing supplier contracts to designing vehicles to managing shipment records. When this amount of documentation is managed manually, records can get lost, mistreated, or abused. An EPR system creates a shared repository for all company documents that simplifies management, allows for tracking changes, and makes documents more accessible.

Depending on a company’s infrastructure, a document repository can be cloud-based or local. It also needs to have a secure access control system to protect documents from negligent harm and malicious actions.

Analytics and reporting. An ERP solution collects a lot of data about many business processes, so it can help automotive companies turn raw data into actionable insights. For example, it can calculate KPIs of various processes, detect data inconsistencies that may indicate production issues, generate reports for internal and external audits, etc.

Analytical and reporting features usually incorporate big data algorithms and business analysis tools. They can also use AI algorithms to detect data anomalies and suggest optimizations.

Integrations. Automotive companies often use a suite of corporate software for HR management, production lifecycle management, and customer relationship management. An ERP system has to be able to exchange data with such software to reduce data management overhead and help companies automate workflows. Developers of popular ERP systems offer APIs for seamless integration with popular corporate solutions.

Most ERP solutions on the market offer these core features, and it may seem like more than enough for an automotive company. Yet, many businesses choose to develop custom ERP solutions. In the next section, we explain why.

Related project

Building a Microservices SaaS Solution for Property Management

Explore how a US-based provider of property management software leveraged Apriorit’s expertise to make their platform more flexible, accessible, and convenient for end users.

Custom vs out-of-the-box ERP solution

Building a custom ERP solution for your company may seem like too much effort and investment compared to simply adopting a ready-to-go system. This process requires lengthy preparation, lots of communication with your development vendor, and investment in development expertise. On the other hand, custom automotive ERP software will fit your business perfectly and provide total control over sensitive data.

The choice between buying an out-of-the-box ERP system or building a custom one depends on your business’s goals and resources. Here are the key factors you need to take into account:

| Parameter | Custom ERP system | Out-of-the-box ERP system |

|---|---|---|

| Ease of adoption | Challenging to develop and adopt | Easy to adopt with tried-out instructions |

| Cost | High upfront cost Low maintenance cost | Low upfront cost Subscription fees Additional costs for customization requests Potential hidden costs, subscription cost increases, and maintenance costs |

| Coverage of business use cases | Covers all your business needs | Covers some of your business needs |

| Cybersecurity and data control | Custom data protection mechanisms that comply with your requirements and industry standards | Common data protection mechanisms Limited customization of security features |

| Customization options | Fully customizable development process and final solution | Limited to no customizability |

| Scalability | Can scale according to your business needs and infrastructure | Limited scalability Possible increase of solution cost with scaling |

| Integrations | APIs for all solutions you use | APIs for popular corporate solutions |

| Maintenance and support | Regular fixes and updates from an in-house team or development vendor | Regular updates Limited support for complex issues and requests |

Overall, custom ERP development provides total control over your solution’s capabilities and helps you adjust them to your manufacturing processes. It’s a good option for companies that need to follow particular automotive laws and regulations, integrate a new system into existing corporate infrastructure, and secure sensitive data and intellectual property.

Let’s see what challenges you may encounter during automotive ERP software development.

Related project

Improving a SaaS Cybersecurity Platform with Competitive Features and Quality Maintenance

Our client was looking for experts in cybersecurity and reverse engineering to help them improve their platform. Explore how the Apriorit team helped them develop new features and add support for new platforms.

Challenges of custom ERP development

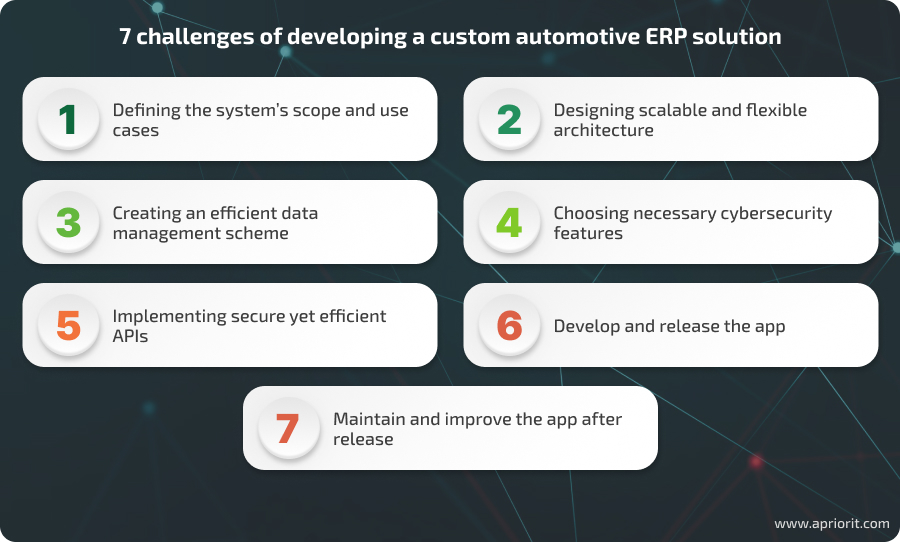

To develop an efficient custom ERP solution for the automotive industry, every step must be properly planned. Here are the key challenges you can encounter and our advice on how you can address them:

Defining the system’s scope and use cases. As useful as it can be, an ERP system can’t cover every business need and use case. That’s why it’s important to figure out your expectations of the system before development starts. Your expectations will impact the architecture design, choice of development tools, system flexibility, and so on.

To ensure that ERP software will be sustainable and will work as expected, we collaborate with a client’s stakeholders and end users during requirements elicitation. Our business analysts (BAs) figure out what the client’s business needs are from their ERP system, how they want it to work and look, and whether it’s possible to implement the system from a technical standpoint. Their work results in detailed requirements that will help developers build the solution that our client expects.

Designing scalable and flexible architecture. The infrastructure must support growing user demands and new features over time. Poorly designed infrastructure can lead to performance bottlenecks, high operational costs, and difficulty in future expansion.

Software architects must assess requirements created by the BAs to create an architecture that satisfies the client’s needs, can scale up and down, and doesn’t require a lot of resources and effort to maintain. For example, they can choose whether a solution will use cloud platforms to support seamless operation in several facilities or on-premises resources for better control over data and regulatory compliance. They can also use containers and microservices to improve the solution’s security and flexibility.

Creating an efficient data management scheme. Providing well-organized data in real time is the core feature of any ERP system. The system has to be able to quickly collect and record data from multiple sources, process it for tasks like visualization and reporting, and analyze records to offer insights. Mistakes in data management can lead to redundant and inaccurate data, resulting in slow and inconsistent databases.

To avoid such issues, Apriorit developers choose a database for each project based on scalability requirements, data types, and data operations. We also use a range of database performance improvement practices to ensure real-time data processing.

Choosing necessary cybersecurity features. ERP systems handle sensitive business information: supply chain contracts, financial reports, vehicle designs, and so on. Developers must anticipate and defend against threats such as unauthorized access, data breaches, and cyberattacks. They also have to make sure their software complies with automotive software requirements like MISRA, automotive SPICE, and ISO 26262.

To make a list of all the security measures your ERP solution requires, analyze applicable industry compliance requirements, national and regional laws, and your business needs. Typically, automotive ERP software requires strong encryption algorithms like AES-256, user authentication with OAuth 2.0 or a similar mechanism, and role-based data access.

Implementing secure yet efficient APIs. A custom ERP solution will require custom integrations with all systems a company uses. To ensure reliable integrations, API developers must balance security and performance features.

Basic API security must include data validation, access management, and security policies. For optimal performance, add performance monitoring tools, rate limiting, and throttling. Also, determine whether your resources allow for vertical or horizontal API scaling, implement automated scaling mechanisms, and ensure these resources are available when APIs need them.

Improving the ERP post-launch. The launch of an ERP system is not the end of its development lifecycle. User feedback and evolving business requirements necessitate ongoing improvements. Without regular updates and bug fixes, an ERP system will sooner or later become slow and ineffective, holding back your business instead of boosting it.

That’s why Apriorit offers support and maintenance services, helping our clients get new features for their systems and providing new APIs to support new corporate software.

Handling these and other challenges requires expertise in data management, cybersecurity, AI, and QA. Apriorit can help you build a custom system that empowers your business. Let’s see how you can leverage our experience in automotive software development.

Read also

Addressing AUTOSAR-Driven Challenges in Automotive SBOMs

Explore how to generate software BOMs that comply with AUTOSAR requirements. Apriorit experts discuss the importance of a software BOM for automotive manufacturers, as well as challenges and best practices.

How Apriorit can help you develop an automotive ERP system

Apriorit is a software development company with TISAX certification and experience working with automotive companies. We can help you develop a custom ERP system that perfectly fits your business needs, providing the exact features and capabilities you need.

Benefit from our experience:

- Full-cycle development. Apriorit’s dedicated team can help you develop a finished product, from requirements gathering to final release, or support you at any stage of your internal software development project.

- Quality assurance. Our QA teams check software quality at each stage of development, making sure that the systems we build work flawlessly upon release.

- Secure development. Apriorit teams adhere to a secure SDLC approach to make sure your product is always protected. We can also conduct security and penetration testing and provide you with tips on improving the protection of your solution.

Conclusion

Developing a custom ERP solution for the automotive industry is a multifaceted process requiring technical precision, strategic foresight, and a deep understanding of business operations. Addressing challenges such as defining the system’s scope, building a scalable architecture, and implementing robust security measures is critical to delivering a solution that aligns with organizational goals.

Solving these challenges and delivering an efficient ERP system requires expertise in several development fields. At Apriorit, we can help you design and implement a solution that will make you more competitive by providing a dedicated team with experience in automotive development.

Drive your automotive business forward

Partner with Apriorit to build an ERP system that satisfies your business needs, compliance requirements, and market demands.