Key takeaways:

- Data analytics is the process of collecting, organizing, transforming, and interpreting data.

- It can help automotive businesses optimize production processes, support autonomous vehicle development, reduce production costs, and make informed decisions.

- Depending on your business specifics and the use cases that you want to cover, you can implement data analytics features into your existing systems or develop dedicated custom software.

- Implementing a data analytics system requires specialists with diverse expertise, from data science to AI development to data visualization.

Automakers and the vehicles they produce generate immense amounts of data every day. Siemens estimates that a high-level autonomous vehicle can generate up to six terabytes of data per year. Companies usually store this data for a time, then dispose of it. But with the help of data analytics, they can use it to improve many business and production processes.

Read on for an overview of the use cases and workflow of data analytics in the automotive industry. You’ll also learn the key benefits and challenges of implementing analytics features and solutions for an automotive business.

This article will be useful for managers and executives of automotive manufacturing and software development companies who are looking for ways to benefit from accumulated automotive data.

Contents:

Using data analytics in the automotive industry

The automotive industry experiences quick transformations and rapidly emerging challenges, such as building flexible global supply chains, shifting production to autonomous and electric vehicles, and increasing connectivity in vehicles and manufacturing equipment. To stay competitive in a dynamic market, businesses need to know exactly how to change their processes. And data analytics can help them with this task.

Data analytics is the process of collecting, organizing, transforming, and interpreting data. It’s used both in science and business to draw conclusions, make informed decisions, and discover new information.

Automotive businesses are uniquely positioned to adopt data analytics as they generate vast amounts of data daily. Automotive manufacturers and tier 1 and tier 2 suppliers use many IoT sensors in their manufacturing equipment to track procurement, production, and shipment. Vehicle sellers record details on every sale and marketing activity. Vehicles with even basic advanced driver assistance systems (ADAS) record data on driving styles, road situations, and vehicle performance.

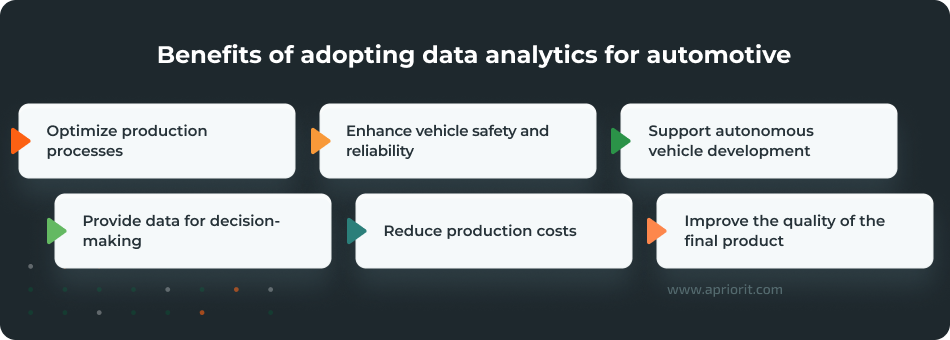

Using data analysis in automotive can result in the following benefits:

The impact of data analytics on automotive businesses will vary from case to case. Let’s see what you can use it for to benefit your business.

Start leveraging data to boost your business

Let us help you define a business case and benefit from data analytics.

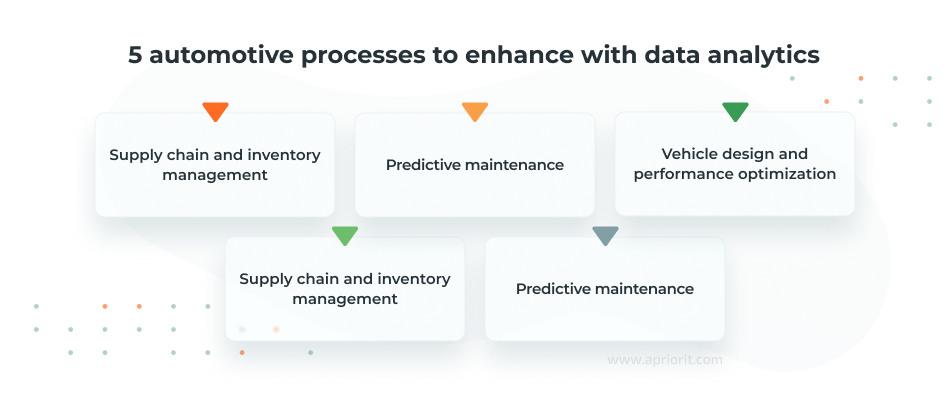

Key use cases of automotive analytics

Depending on your business specifics and the use cases that you want to cover, you can implement data analytics features into your existing systems or develop dedicated custom software. Here’s how your automotive business can use data analytics:

Supply chain and inventory management

Predictive analytics enables manufacturers to accurately forecast material requirements, reducing the risk of stockouts or excess inventory. By analyzing historical trends, market data, and supplier performance, manufacturers can make informed decisions about order quantities and timing, ensuring a seamless supply chain. BMW combined data analytics with AI and blockchain technology to build a flexible and secure supply chain platform that allows the company to minimize waste.

Data analytics also supports supplier relationship management. By evaluating key metrics such as lead times, defect rates, and cost efficiency, manufacturers can identify reliable partners and address issues with underperforming suppliers. Additionally, analytics tools can predict potential risks in the supply chain, such as supplier insolvency or seasonal changes.

Predictive maintenance

Predictive maintenance leverages data analytics to monitor equipment and vehicle health, anticipating failures and reducing unplanned downtime. This approach is especially valuable in automotive manufacturing and fleet management, where operational continuity is critical.

Predictive maintenance systems analyze parameters such as temperature, vibration, and pressure by collecting data from IoT sensors installed on machinery or vehicles. In automotive manufacturing, predictive maintenance helps to optimize production schedules by reducing unexpected equipment failures. For example, General Motors employs predictive analytics to monitor its assembly lines, ensuring that machinery operates at peak efficiency. This not only reduces repair costs but also minimizes waste caused by defective production runs.

Additionally, predictive maintenance enhances vehicle safety by addressing potential issues before they escalate. Advanced analytics can identify factors like abnormal tire wear on vehicles, prompting timely replacements and preventing accidents. This proactive approach improves reliability and customer satisfaction while reducing warranty claims.

Read also

Predictive Maintenance in the Automotive Industry: Benefits and Challenges

Improve your fleet’s efficiency and reliability. Apriorit experts will guide you through key uses of predictive maintenance algorithms and how to implement them.

Vehicle design and performance optimization

Data analytics allows automotive companies to create safer and more efficient vehicles. By analyzing customer feedback, sensor data, driving patterns, and other data, manufacturers gain valuable insights into user preferences and vehicle performance under real-world conditions. BMW uses analytics to assess how its vehicles perform in extreme weather conditions, using this data in the design process to improve vehicle durability and reliability.

Furthermore, data analytics allows manufacturers to fine-tune fuel consumption for internal combustion engines and energy consumption for electric vehicles. Analysis of driver behavior, vehicle performance in different conditions, the impact of certain parts on vehicle behavior, and other parameters can provide automotive designers with insights and ideas for new fuel and energy optimization mechanisms.

Fleet management

The key use case for data analytics in fleet management is route optimization. Using real-time traffic data and historical patterns, analytics tools can identify the most efficient routes for deliveries or services, reducing fuel consumption and travel time. UPS, for instance, leverages advanced analytics to minimize left turns, saving 10 million gallons of fuel annually.

Driver behavior analysis can help fleet managers identify unsafe driving practices and create targeted training programs for their drivers. For this purpose, they can analyze and visualize data collected from vehicle sensors, GPS systems, and recordings of road accidents.

Fleet managers can also use data analytics to analyze fuel and energy consumption patterns and identify cost-saving opportunities. For example, electric and hybrid vehicle fleets can optimize charging schedules based on usage patterns and energy costs in different countries and regions, and at different times of the day.

Sales and marketing

Analyzing customer behavior, market trends, and historical sales records can help an automotive business create targeted campaigns and find a balance between manufacturing and customer demands.

Predictive analytics based on sales records and market trends helps automotive companies forecast market demand and justify decisions on pricing, inventory, and product launches.

Automotive sales and marketing can benefit from a variety of data analytics techniques:

- Customer segmentation helps companies identify customer groups and tailor marketing messages to resonate with each segment. Segmentation is usually based on customers’ purchase histories, demographic data, and online behavior.

- Sentiment analysis, which examines social media posts and customer reviews, helps a company understand how an audience perceives the brand and what should be done to change the brand image. Automotive companies can use this technique to address negative feedback, highlight their strengths, and refine marketing approaches.

- Real-time campaign performance tracking and visualization allow marketers to assess the effectiveness of their efforts, adjust strategies, and allocate resources more efficiently.

Leading automotive manufacturers enhance their sales and marketing with data analytics. For example, General Motors cooperates with Adobe to create personalized marketing campaigns in real time, targeting specific customer preferences and conversion rates. Tesla monitors social media to assess the company’s public image. They also analyze customer feedback through the Tesla app and forum and implement requested changes.

As data analytics evolves and relies more on innovative technologies like AI, it will gain new applications in the automotive sector. Some of the trends and upcoming changes we can already predict.

Related project

Leveraging NLP in Medicine with a Custom Model for Analyzing Scientific Reports

In a recent project, we helped an international medical research organization level up their data analysis with AI. The new custom NLP model helps the client analyze and summarize scientific reports and medical research with over 92.8% accuracy.

The future of data analytics in automotive

Trends in automotive data analytics go hand in hand with changes in the automotive industry. Here are the key changes you can anticipate in the coming years:

- More data from vehicle connectivity. As vehicles become more connected to each other and the environment — and get more autonomous capabilities — they provide more data for analytics. And more data makes analytics results more precise and actionable.

- Greater use of digital twins. A digital twin is a virtual copy of a vehicle created to emulate its performance, anticipate issues, and run simulations. Some fleet management companies and manufacturers already use digital twins for their fleets. With more data on vehicle operations, it’s easier to create an accurate digital twin and use it for analytics.

- Personalization of driving systems. ADAS adjusts to driving style and personal preferences to improve road safety. Data analytics can help infotainment systems adapt to individual preferences, offering personalized entertainment, navigation, and vehicle settings.

- Enhanced data security and compliance requirements. Vehicles collect sensitive information about their drivers, and automotive companies must ensure a high level of data protection. Analyzing new threats to sensitive data and vehicles will help them discover new security measures.

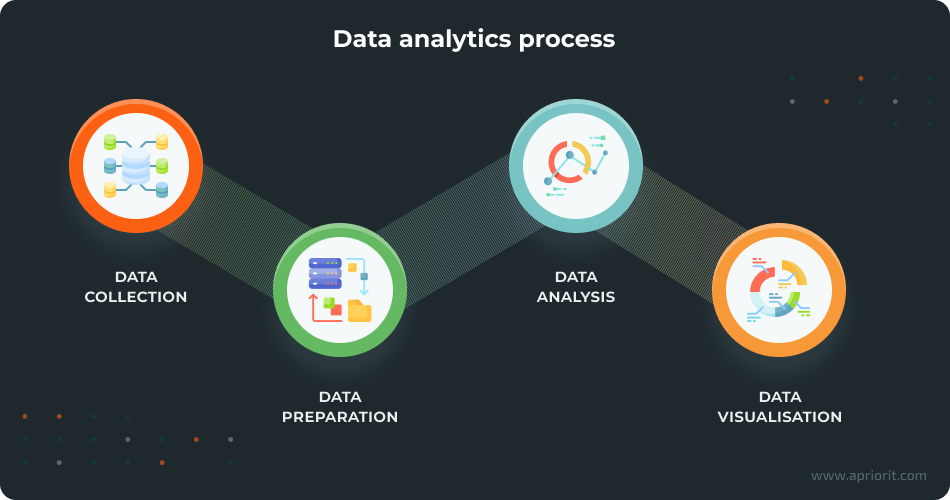

How data analytics works in automotive

The general data analytics workflow is similar for any business and use case. Let’s examine the key stages and how they can be applied in an automotive company:

- Data collection

To provide meaningful results and useful insights, data analytics has to be based on huge amounts of relevant, diverse, and accurate data. The type of data you should collect depends on the goal of your data analytics algorithm. Here are the key sources of data in an automotive business:

- Manufacturing sensors from IoT-enabled machinery and assembly lines

- Supply chain systems and communication with suppliers

- Real-time on-board vehicle sensors

- Vehicle telematics systems

- Historical data from CRM and ERP systems

- Customer surveys and social media sentiment

- Data preparation

Once data is collected, you need to make sure it’s usable for a data processing algorithm. Data preparation includes activities like:

- Removing errors in data

- Filtering out redundant, irrelevant, incomplete, and corrupted data points

- Merging similar data in datasets from different sources

- Matching records by unique identifiers like VIN (Vehicle Identification Number)

- Identifying missing data points and filling gaps

- Verifying that all critical data has been collected

- Data analysis

At this stage, you apply the technology of your choice to analyze the collected data and draw conclusions. Here are the key technologies and approaches you can use:

- Artificial intelligence is best for solving complex multi-variable problems like anomaly detection and simulations of real-life situations. AI can provide data for decision-making, determine flaws in processes and designs, and help with marketing ideas.

- Machine learning helps recognize patterns in data and classify records. It’s useful for predictive maintenance, sales estimations, and customer segmentation.

- Statistical analysis methods are used for identifying trends and testing hypotheses. Statistical analysis can help you find correlations in manufacturing and sales data, driver behavior and fuel and energy consumption, and so on.

- Big data analytics is especially good for processing real-time data from vehicle sensors and vehicle-to-everything (V2X) communication to optimize fleet operations.

- Simulation and modeling use historical records to predict the outcome of a certain situation or change. For example, they can help to build digital twins for vehicles or anticipate how design changes will affect a vehicle’s performance.

- Data visualization

The results of data analysis can be difficult to quickly understand and interpret. This last stage of the process allows you to turn the results into presentable and actionable insights. You can visualize information with:

- Dashboards, charts, and histograms

- Heat maps, bar charts, and pie charts

- 2D and 3D visualizations

- Gantt charts of analytics predictions and business goals

- And more

Each stage of data analytics requires meticulous and focused labor, which takes a lot of time if performed manually. That’s why companies often automate the process, in whole or in part.

Adopting, fine-tuning, and automating a data analytics pipeline presents challenges that require expertise in software development and analytics. Let’s examine the key issues you can face and how the Apriorit team solves them.

Read also

AI in the Automotive Industry: 7 Key Applications for a Competitive Advantage

AI plays a big part in various types of automotive software, including data analytics algorithms. Discover how it can improve automotive processes and what you need to start adopting AI.

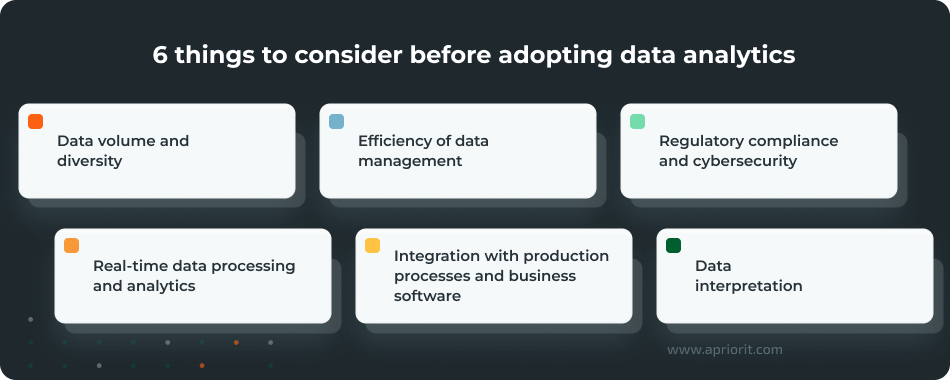

6 factors in implementing automotive data analytics

The size and complexity of the automotive industry, along with the rapid changes it is undergoing, make implementing and maintaining data analytics challenging. On the one hand, you need to build a system that factors in hundreds of data sources and analysis parameters. On the other hand, this system has to be flexible and scalable enough to keep up with growing business demands. In addition, automotive systems process sensitive data, from vehicle diagnostics and GPS records to customer profiles, making security and regulatory compliance a top priority.

Here are the key challenges of data analytics you can encounter when adopting a custom solution:

Data volume and diversity

With gigabytes of new records generated daily by IoT sensors on manufacturing equipment, on-board vehicle diagnostics and telematics, and communication with suppliers and customers, efficiently storing and using new data becomes a challenge. Businesses need a way to verify data quality, record new data in usable formats, and avoid errors and duplications. Otherwise, their data analytics solutions will use low-quality data and return incomplete or flawed conclusions.

How do we approach this?

To address this issue, we start by analyzing data sources in a client’s business. We examine devices and systems that generate data, analyze the data formats, and draft an automated pipeline to connect and manage all data sources. Tools like Apache Kafka and AWS Glue can efficiently handle high volumes of data. Additionally, we can help you adopt data lakes — centralized repositories for structured and raw data. Advanced analytics tools that leverage AI and machine learning can process unstructured data, simplifying data preparation and analysis.

Efficiency of data management

This challenge stems from the same issue as the previous: a lot of data generated in a given period of time. Trying to process numerous data records using inefficient management and storage tools may result in long response times, freezes of data analytics features and corporate systems, or errors.

For example, a manufacturer might need to analyze sensor data from multiple factories to identify production bottlenecks or quality issues. At the same time, they may need to merge this sensor data with data on inventory levels, supply chain statuses, and workforce productivity. If data processing systems are sluggish or fragmented, delays in delivering insights can impact operations, slow down decision-making, and lead to flawed results.

How do we approach this?

Solving this challenge starts with the design of data management and analytics features. We take into account the volume and nature of your data, required operation speed, and scalability options when creating the data architecture and ELT processes. In an existing system, adding automation, process scheduling, and high-performance computing frameworks can help improve efficiency.

Regulatory compliance and cybersecurity

Cyber attacks on connected cars regularly expose private driver and passenger data, compromise safety systems, and even create dangerous road situations. Malicious actors also often target manufacturing sites and supply chains, trying to get proprietary data about manufacturing techniques or shipment details. As malicious actors can steal, change, or delete data used in analytics, these attacks introduce the risk of manipulated results.

How do we approach this?

Two ways of ensuring the security of automotive data are complying with relevant laws and standards and implementing the best cybersecurity mechanisms.

To ensure regulatory compliance for your product, we start by determining relevant laws, regulations, and standards. These may vary depending on your type of automotive business, region of operation, and data types you manage. A good place to start is by checking and implementing requirements of the GDPR, ISO/IEC 27001, ISO/SAE 21434, AUTOSAR, and TISAX.

As for cybersecurity practices, data encryption, multi-factor authentication, and access management are a must. Regular cybersecurity audits help you make sure your data analytics and management systems are reliably protected from threats.

Read also

Addressing AUTOSAR-Driven Challenges in Automotive SBOMs

Software bills of materials are essential to managing the ever-growing complexity of automotive systems and data. Get Apriorit’s perspective on building SBOM generation systems in compliance with AUTOSAR.

Real-time data processing and analytics

Real-time analytics powers processes like predictive maintenance, the use of digital twins, and fleet management. Processing data from connected vehicles or production lines on the fly helps to detect and address equipment and vehicle malfunctions before they cause downtime. Latency in processing real-time data reduces the efficiency of such systems and, in some cases, can make them completely useless.

How do we approach this?

Implementing real-time analytics requires low-latency networks, high-performance computing resources, and software capable of processing data streams without delays. For such projects, we choose scalable cloud platforms and stream processing frameworks like Apache Flink that can effectively handle continuous data flows.

Integration with production processes and business software

Seamlessly integrating data analytics into automotive production processes and vehicle software is a significant hurdle because of the diversity of devices and systems within one business. They generate different types and amounts of data; some work in real time, and some share data on demand. Data analytics services must interact with these devices and systems to provide actionable insights, but low-quality integrations or incompatibilities between legacy and modern platforms often hinder integration.

How do we approach this?

There are several ways of improving integration quality depending on your situation and type of product:

- Develop custom APIs to offer seamless scalable integration with rare solutions (though building them requires development expertise).

- Using middleware solutions or integration platforms such as MuleSoft, which provide lots of pre-built assets and APIs.

- Standardize data formats across systems and adopt protocols like OPC UA for industrial IoT to further ensure compatibility.

Data interpretation

While data analytics can provide valuable insights, making those insights understandable and actionable is often challenging. The results of data analysis are often presented in formats that are too technical or abstract for non-experts, making it difficult for stakeholders to extract useful conclusions from them.

Using AI models or machine learning algorithms for analytics can add another layer of complexity. These tools can identify patterns and trends that humans might miss, but understanding why a certain outcome occurred or how to use it effectively can be difficult. For example, an AI model might suggest that a specific set of driving behaviors correlates with higher accident rates, but it’s up to humans to interpret how to adjust vehicle design or driver training to mitigate risk.

How do we approach this?

Data analytics processes must include visualization tools like Microsoft Power BI or Tableau (or a custom alternative) to make analytics results actionable and presentable. We recommend creating templates for your company’s most common data analytics applications. You can also ask domain experts to add their notes and recommendations.

Read also

Automotive Cybersecurity Testing 101: Requirements, Best Practices, and Tips on Overcoming Challenges

Explore tips from Apriorit experts on the specifics of security testing in automotive. Learn about common attacks on automotive solutions and the best ways to test them.

Build a data analytics solution with Apriorit

Implementing a data analytics system requires specialists with diverse expertise, from data science to AI development to data visualization. With a global IT talent shortage that could result in about $8.5 trillion in unrealized annual revenue by 2030, assembling such a team in-house is a challenge.

Apriorit can provide you with individual specialists or gather an entire team to engineer the solution you need. With our specialists, you get:

- Strong expertise in AI development, embedded solutions, data management, and cloud computing

- Seamless integration of data analytics with your systems and devices

- Full-cycle development services, from project discovery to development, testing, and post-release maintenance

- A development process secured with SDLC principles

Being a TISAX-certified company, we know what automotive companies need from data analytics and custom software. And we have what it takes to deliver it.

Conclusion

As the automotive industry moves to autonomous vehicles, data analytics increases its impact on vehicle design, manufacturing, and sales. From operational planning and predictive maintenance to personalized customer experiences, the applications for data analytics are vast and transformative.

However, the road to fully leveraging data analytics capabilities for automotive businesses is not without challenges. Managing the sheer volume and complexity of data, ensuring security, integrating analytics with existing processes, and addressing talent shortages are significant hurdles that require strategic planning and investment.

Our dedicated teams with experience in data analytics, AI development, and cybersecurity will gladly help you overcome these and other challenges in your development journey.

Drive your business to success with data analytics!

Let us build a tailored solution that will help your business stay competitive.