Key takeaways:

- Businesses that use warehouse drones need dedicated software solutions to efficiently manage and monitor them.

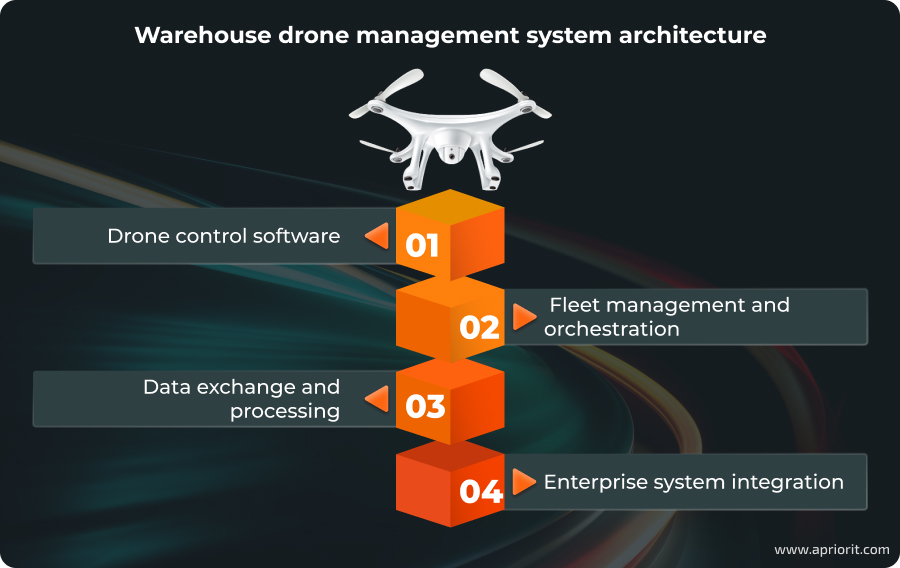

- A warehouse drone management system usually includes components for drone control, fleet management, data processing, and enterprise system integrations.

- Companies that have unique workflow requirements, use custom drones, or have to comply with strict regulations should consider building a custom solution instead of trying to upgrade an existing off-the-shelf warehouse management system.

Applying drones for warehouse and inventory automation is tricky, especially on the software level. Existing warehouse management systems may have severely limited drone support capabilities, or none at all.

But with drone-powered warehouse automation, businesses can leverage benefits like process automation, improved worker safety, and lower expenses. That’s why, to enhance their warehouse management systems, they often need custom drone app development.

We have prepared an overview of the software side of warehouse drone management. Leveraging our experience in embedded software development and projects in retail and logistics, we analyze the current role of drones in warehouse management, use cases of drone management systems, key components, and basic features to consider for a warehouse drone management system. This article will be useful for software development teams and organizations looking into the possibility of building a custom drone management app.

Contents:

The role of drones in warehouse automation

It’s no longer possible to manage deliveries using only human efforts.

Modern warehousing is becoming increasingly automated and heavily relies on Internet of Things (IoT) systems and robots to track, manage, and ship items as quickly as possible.

Businesses can use two types of robots for warehouse and inventory automation: unmanned aerial vehicles (UAVs) and autonomous mobile robots (AMRs). In this article, we focus on UAVs.

Aerial drones operate in three-dimensional space, making them an efficient solution for managing inventory in high-density storage environments.

Drones help warehouse employees by:

- speeding up their work

- improving warehouse efficiency

- reducing the risk of physical harm

They also reduce the cost of warehouse management. Using UAVs, or drones, allows warehouses to partially automate the following activities:

- Inventory audit. The primary use case for drones in a warehouse is scanning item barcodes and radio frequency identification (RFID) tags to calculate item quantities and record locations. Using drones instead of humans speeds up the process and reduces the risk of human error.

- Warehouse capacity calculations. Drones can distinguish between full and empty slots and generate spatial layouts of a warehouse. Collecting data about the number and locations of empty slots in real time allows warehouse workers to efficiently distribute, store, and ship items.

- Item tracking. Finding a particular box in a large warehouse is a time-consuming task even if an employee knows in what area it should be stored. A drone adds the exact location of each item to the warehouse database so it can find any box fast.

- Video surveillance. Every warehouse has a traditional surveillance system that relies on stationary cameras, which have their blind spots. Using drones makes warehouse surveillance more flexible and comprehensive, improving warehouse security.

- Remotely controlled physical manipulations. Warehouse workers can perform potentially dangerous tasks remotely using drones. UAVs built specifically for working in warehouses can lift and shift lightweight objects. They can also work in dangerous environments: in dimly lit places, in narrow passages, on high shelves.

To perform each of these tasks, drones need complex management software that coordinates hardware activities, collects data in real time, and constantly communicates with warehouse management software. In the next section, we analyze the architecture of such drone management software, focusing on its key components.

Want to connect devices seamlessly?

Our team delivers end-to-end embedded and IoT solutions, ensuring security, performance, and scalability. Let’s build technology that drives your business forward.

Key elements of a drone management system architecture

A warehouse drone management system is a complex software platform designed to coordinate, control, and optimize drone operations within a warehouse environment. It enables fleet management, navigation, data processing, system integration, and real-time decision-making, ensuring that drones contribute efficiently to warehouse automation.

The architecture of any drone management software depends on its goals, use cases, and hardware capabilities. However, any warehouse drone management system includes several interdependent layers:

1. Drone control software

Warehouses need software that allows them to control UAVs in real time, executing key drone operations:

- Flight control — Ensure precise movement of a drone, maintain stability and set altitude

- Navigation and collision avoidance — Dynamically adjust drone movement using sensors like LiDAR, cameras, inertial measurement units, and simultaneous localization and mapping

- Task execution — Perform tasks like stock scanning, barcode recognition, and item transportation

- Power management — Monitor drone battery levels and ensure efficient energy use

As most of these tasks are time-sensitive, drone control software often runs on a real-time operating system (RTOS). Sometimes, businesses also may need to develop a drone battery management system to improve the energy efficiency of their drone fleet.

User-oriented drone management software is usually delivered as web and mobile applications.

To ensure precise control over UAVs, user-oriented applications need to communicate with drones in real time, support a stable internet connection, and have an easy-to-use and intuitive user interface.

Related project

Developing Software for a Drone Battery Charging and Data Management Unit

Accelerate your drone management capabilities with our embedded and mobile development expertise. Discover how we improved system control and operational efficiency to drive better performance.

2. Fleet management and orchestration

The role of fleet management and orchestration software is to ensure that all warehouse operations are conflict-free and well-optimized, preventing possible inefficiencies and downtime.

This layer represents the central coordination system of a warehouse drone management system, handling four important vectors:

- Task assignment — Distribute tasks like item scanning, transportation, and inspection among warehouse drones

- Drone coordination — Prevent interference between different drones operating within the same space

- Traffic control and scheduling — Optimize drone movement routes to improve safety and efficiency

- Monitoring and diagnostics — Analyze drone health, battery state, and key performance metrics

3. Data exchange and processing

Drones collect and generate tons of data, from high-resolution images and videos to 3D mapping data and lidar scans. A warehouse automation platform needs a layer that facilitates reliable, secure, and low-latency communication to maintain a stable data flow between UAVs and the coordination system.

Depending on warehouse needs, businesses may opt for either edge computing, centralized cloud processing, or a combination of the two.

Stable drone connectivity is essential, particularly in environments with potential interference from warehouse infrastructure or poor network coverage. To establish and maintain such communication, warehouse drone management systems can leverage different communication protocols:

- MAVLink — A lightweight protocol often used for drone telemetry and control. While MAVLink is mostly used for outdoor UAVs, it can also be applied in systems that operate indoors

- MQTT — A lightweight protocol for non-time-critical data aggregation

- ExpressLRS — A fast open-source protocol for controlling drones and receiving telemetry data

- LoRa — A low-speed and long-range protocol for non-time-critical data aggregation

- ZigBee — A low-power close-range mesh style protocol that allows for coordination between drones

Warehouse management systems also rely on wireless network technologies, like Wi-Fi and LTE/5G cellular networks, to enable high-speed connectivity for warehouse operations.

This layer of the warehouse drone management system should also enable efficient processing of all data collected by drones. Usually, this requires implementing capabilities for sensor data processing and warehouse database synchronization.

Advanced solutions may also include analytics modules that detect anomalies and warehouse inefficiencies or enable predictive maintenance for connected drones.

Read also

How to Create an SBOM to Secure Your Embedded System

Improve your embedded device security with a Software Bill of Materials (SBOM). Discover how having a well-structured SBOM can help you mitigate risks, enhance supply chain security, and ensure compliance with evolving cybersecurity laws and regulations.

4. Enterprise system integration

In order for drone-based warehouse automation to align with business goals, drone operations must be integrated with the existing enterprise or warehouse software. This requires implementing:

- API-based connectivity with warehouse management system (WMS) and enterprise resource planning (ERP) platforms

- Automated synchronization for real-time inventory updates

- Multi-system interoperability, ensuring that the drone management system can work alongside robotic arms and other warehouse automation tools

These four elements represent only the core of a drone management system. Within these elements, vendors implement various features and technologies to make their software more technologically advanced and competitive on the market. In the next sections, we look at the basic technology stack your team can use to create a software system for drone management and the key features to implement in such a system.

Technology stack for a warehouse drone management system

The choice of technology stack for a warehouse drone management system depends heavily on the specific tasks this system is expected to handle, the types and models of drones it’s expected to support, and its planned integration and connectivity abilities.

Below, we outline the key technologies that your development team may use when designing a warehouse drone management system:

Table 1: Warehouse drone management system technology stack

| Category | Technologies and frameworks | Purpose |

|---|---|---|

| Embedded OS for drones | PX4, ArduPilot, Zephyr RTOS, FreeRTOS | Real-time control, sensor fusion, and flight stabilization |

| Embedded software | C, C++, Rust, MicroPython | Low-level control, high-performance execution, and memory safety |

| Backend development | Python (FastAPI, Flask, Django), Node.js (Express, NestJS), Go (Gin, Fiber), Java (Spring Boot, Quarkus) | Drone fleet coordination, API management, and WMS/ERP integration |

| Database management | PostgreSQL, MongoDB, Redis, TimescaleDB, blockchain | Storing drone telemetry data, inventory data, and historical analytics |

| Communication protocols | MAVLink, MQTT, ExpressLRS, LoRa, ZigBee | Real-time data exchange between drones, control centers, and backend systems |

| Wireless connectivity | Wi-Fi 6, LTE/5G | Ensuring low-latency, high-reliability communication between drones and systems |

| AI and computer vision frameworks | TensorFlow, PyTorch, OpenCV, YOLO, ONNX Runtime | Object detection, barcode recognition, navigation, and predictive analytics |

Key features for a warehouse drone management system

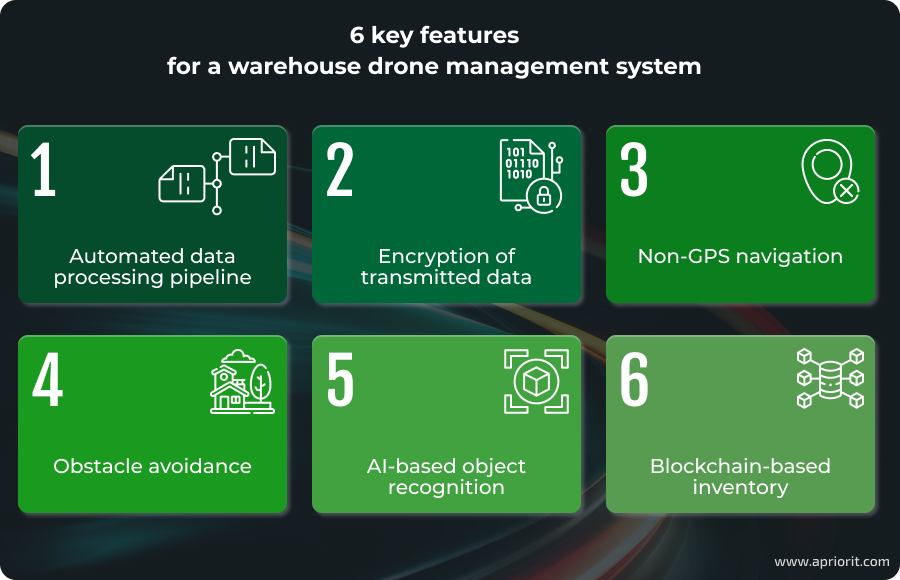

Modern warehouse drone management systems are technologically advanced solutions that operate using various drivers, AI algorithms, and even blockchain-based storage. Some technologies and features are a must for any drone management system. Others are optional, as they are needed only to perform a particular task.Let’s take a look at the key drone management system features to consider.

1. Automated data processing pipeline. A drone has to collect data about items in the warehouse and synchronize it with the warehouse management system and user application as fast as possible. When you create drone data management software with an automated pipeline, data moves around the warehouse IT environment without any involvement from employees. In this way, the drone management system helps to keep the warehouse database up to date and eliminates the risk of human errors when manually inputting data.

2. Encryption of transmitted data. Hackers may attempt to steal data collected by drones or try to intercept wireless protocol data to hijack drones or cause other damage to the company. To protect sensitive information from falling into the wrong hands, make sure that all data transmitted between drones, user apps, the control platform, and your WMS is properly encrypted.

Read also

Top 7 Methods of Data Encryption in Android Applications

Protect user data with the best encryption for Android. We compare seven encryption methods, detailing their security levels, performance impact, and ease of implementation so you can make an informed choice for your mobile application.

3. Non-GPS navigation. Usually, drones rely on stable GPS connections to navigate. However, this can be challenging in a warehouse because GPS signals are usually weaker inside a building. That’s why warehouse drones have to be equipped with distance sensors, lidar sensors, and inertial measurement systems that enable highly precise calculations of a drone’s position in closed areas.

4. Obstacle avoidance. Using drones in a warehouse can both make it a safer place for employees and endanger them. A drone has to be able to recognize objects on its route — including employees — and avoid them. To do that, a drone’s sensors should be able to measure proximity to the nearest objects, and the drone must be able to change its route accordingly.

5. AI-based object recognition. There are many issues a drone can face when scanning a barcode. The barcode may be placed upside down or in an unusual place on the box, or it may be in a non-standard format. Because of these issues, a drone may scan barcodes incorrectly or skip them altogether. Implementing AI-based optical character recognition and image recognition helps the drone management system better adapt to new conditions and efficiently process scans of various types.

Read also

Navigating AI Image Processing: Use Cases and Tools

AI is redefining image processing. From object detection to noise reduction, explore how AI-driven techniques enhance visual data analysis and open new possibilities for various industries.

6. Blockchain-based inventory. Keeping warehouse inventory organized and protected is another important task for drone management systems. Some vendors use blockchain-based systems along with traditional databases, as this technology helps to protect data from undesired changes, theft, and hacking. Blockchain-based inventory gets data on items in the warehouse from drones and converts it into blocks of data that cannot be edited and tampered with.

These are just a limited set of features and technologies that you can implement during warehouse drone management system development to make your system secure, efficient, and convenient. When deciding on the final set of capabilities for your WMS, you should consider the demands and needs of your end users.

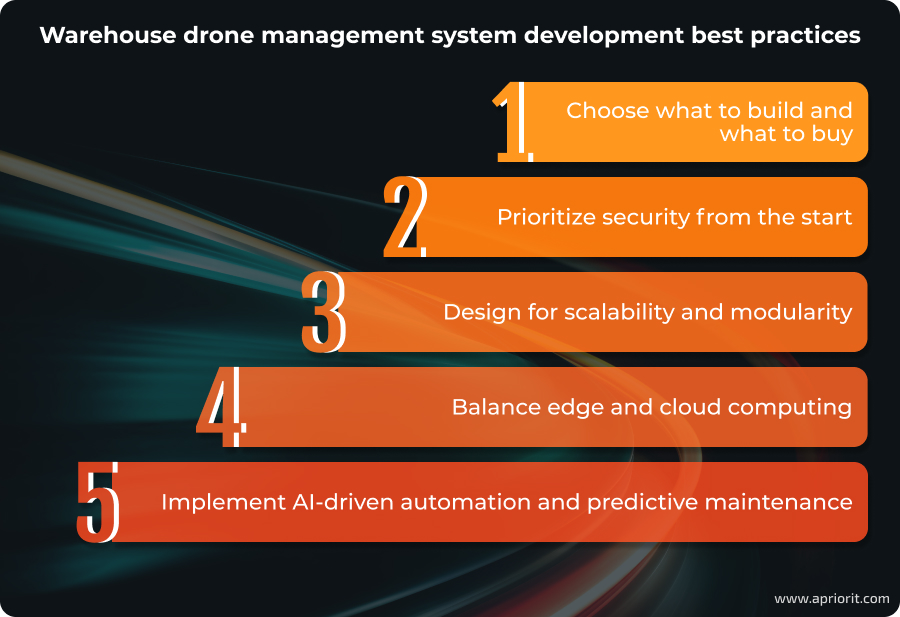

Apriorit’s best practices for warehouse drone management software development

Depending on your business specifics, you may need to build a dedicated warehouse drone management system from scratch or add specific drone management capabilities to an existing platform. Either way, it’s crucial that your development team ensures the productivity and security of the resulting solution.

An efficient warehouse drone management system must be able to handle real-time drone coordination, support low-latency communication, and seamlessly integrate with the entire warehouse infrastructure.

Based on Apriorit’s experience working on drone management systems, we have outlined several key recommendations:

1. Choose what to build and what to buy

While off-the-shelf solutions can’t fully satisfy a particular business’s needs and often provide limited customization options, custom development of an entire system from scratch requires extensive resources that not every business can allocate. This is why many organizations opt for leveraging existing WMS platforms and flight control frameworks while developing a custom back end for fleet management, AI processing, and WMS integration.

Developing a custom warehouse drone management system will be reasonable for businesses that have:

- Warehouse operations with unique requirements that off-the-shelf solutions can’t fully support

- Highly specialized drone fleet and automation setups that require deep integration with existing logistics software

- Strict security, regulatory, or data privacy policies to comply with, specifically if full control over software and infrastructure is required

At Apriorit, we have a team of experienced business analysts who can help you determine the perfect development strategy for your project and assist with any research and discovery activities, from market analysis to requirements elicitation.

Read also

Requirements Elicitation: Reasons, Stages, Techniques, and Challenges

Poorly defined requirements can derail your project. Discover expert techniques for identifying stakeholder needs, minimizing ambiguity, and setting up your project for success with strong requirement elicitation strategies.

2. Prioritize system security from the start

A warehouse drone management system often handles sensitive warehouse data and controls physical drone movements, making it a high-risk target for cyber threats if not properly secured.

Furthermore, embedded systems can be extremely vulnerable to hacking. Usually, they are equipped only with a small CPU and a small amount of memory. Overloading them with too many tasks creates delays in the real-time work of the system and may cause incorrect task execution.

Some developers neglect data protection features to use more resources for core system functionality, which leads to data leaks and breaches. If you want to deliver a highly secure product, your team needs to integrate necessary cybersecurity measures into the development process rather than treat system security as an afterthought.

Here are some essential security considerations for your project:

- Secure all communication channels between drones, control systems, and backend services with end-to-end encryption (TLS, AES-256)

- Implement role-based access control to restrict unauthorized users from issuing drone commands

- Ensure firmware integrity to prevent tampering and unauthorized modifications to drone software

- Protect API endpoints using authentication and rate limiting to prevent system abuse

At Aprorit, we follow the principles of a secure software development lifecycle, incorporating additional security measures into every stage of the software engineering process. This helps us build products that are highly secure — and do it in a secure manner.

You can learn more about the basics of a secure SDLC on this page.

Read also

How Does TLS 1.3 Work? Protocols, Key Attacks, Security Practices

TLS ensures secure data exchange online, but how does it work? This article clearly breaks down encryption, handshakes, and authentication.

3. Design for scalability and modularity

Warehouse operations grow and evolve, requiring a system that can scale alongside increasing demand. When your team builds a warehouse drone management system, it’s best to ensure that the system either supports or can be adjusted to accommodate:

- Changes in warehouse workflows

- Changes in the number of drones operating in parallel

- Complex fleet coordination across different warehouse sites

- Integration with additional automation technologies, such as robotic picking systems, conveyor belts, and automated guided vehicles

One way to achieve this is by designing a modular architecture, where core components like fleet management, navigation, and computer vision are loosely coupled yet interoperable. As a result, you’ll be able to introduce incremental upgrades without disrupting existing operations.

With Apriorit’s help, you can build a brand-new product with a flexible modular architecture or introduce necessary flexibility to your legacy system by migrating it from a monolithic to a microservices-based architecture.

Read also

Building a Microservices Architecture Using Azure Service Fabric

Learn how to design scalable, resilient microservices with Azure Service Fabric. Explore key concepts, benefits, and best practices.

4. Balance edge and cloud computing

As we mentioned earlier, warehouse management systems usually leverage both edge computing and cloud computing. And it’s important to understand the difference between these two approaches:

- Edge computing is ideal for time-sensitive tasks. This type of computation should be implemented for navigation, obstacle avoidance, real-time barcode scanning, and any other task that has critical latency constraints.

- Cloud computing should only be applied for resource-intensive tasks. Common examples of such tasks include aggregated data analysis, anomaly detection, AI training, and predictive maintenance.

Apriorit engineers can assist your team with determining the best data processing approach for your project and configuring and maintaining your own cloud infrastructure.

Read also

Multi-Cloud Computing: Use Cases, Pros, and Cons for Enterprises

Is a single-cloud model limiting your business? Multi-cloud computing enhances scalability, security, and vendor flexibility. Learn how to design a resilient architecture and avoid common pitfalls.

5. Implement AI-driven automation and enhancements

AI-driven automation allows businesses to optimize drone efficiency, minimize operational downtime, and reduce human intervention.

When enhanced with AI-driven capabilities, a warehouse drone management system can go beyond simple drone coordination. AI-powered features allow for enhanced navigation, improved object recognition, optimized workflows, and predictive maintenance for drone systems.

Apriorit’s artificial intelligence experts know how to choose the right AI algorithms and integrate them into existing systems with security and efficiency in mind. We can also assist you with building a custom solution to enable predictive maintenance for your drone fleet.

Read also

Predictive Maintenance in the Automotive Industry: Benefits and Challenges

Predictive maintenance is the future of automotive reliability. Explore how machine learning and IoT sensors help detect potential failures before they happen, improving efficiency and reducing costs.

Conclusion

UAVs can partially automate various warehouse and inventory activities, enabling businesses to efficiently use their resources and create safe working conditions for their employees. However, working with drones within a warehouse environment requires dedicated solutions that can efficiently operate UAVs and integrate with ERP and WMS systems.

Businesses can build fully customized warehouse management systems from scratch or integrate drone management capabilities into existing systems. In both cases, they will need the assistance of an experienced software engineering team. This is especially true for tasks that require niche expertise, like implementation of predictive drone maintenance functionality or development of a drone battery charging system.

At Apriorit, you can find the exact expertise and skills your project needs to successfully deliver an efficient drone management solution. Leverage our robotics software development services to achieve your business goals.

Struggling with your off-the-shelf software?

Get a custom-built solution designed specifically for your business. From ideation to deployment, we deliver secure, high-quality software tailored to your industry’s needs and requirements.